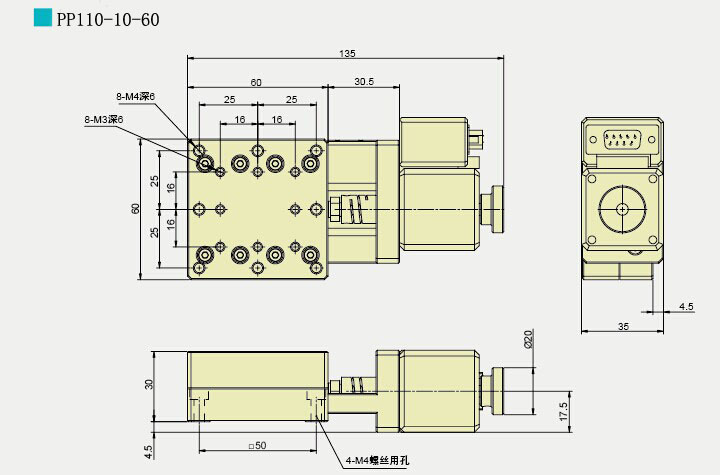

| Model Number | PP110-10-60 |

| Platform | 60×60mm |

| Travel Range | ±10mm |

| Stepper Motor | 35 Stepping Motor with 2-Phases + Screws∅8×P1 |

| Travel Guide | Cross Roller Guide |

| Step Angel | 1.8° |

| Phase Current | 0.8A |

| Resolution Ratio Step/Half step | 5μm/2.5μm |

| Max Velocity | 2.5mm/sec |

| Repeating Positioning Accuracy | 3μ |

| Absolute Positioning Accuracy | 10μ |

| Parallelism | 30μm |

| Driving Parallelism | 10μm |

| Load Capacity | Parallel:10kgf(98N) Vertical:5kgf(49N) |

| Weight | 1.1kg |

| Surface Preparation | Aluminum Alloy-Black-anodized |

The design of limited switches and zero switch protect products and supply convenience;

Standard interface is convenient for singal’s output.

The back of motorized stages has handwheel , it is for convenience for adjustment;

Standard hole is so easy for combine with other units, ensure convenience for multi-dimensional system;

standard stepper motor and DB9 interface, choose to any controller according to requirement

We have Processing equipment: CNC 10 sets, Lathe 8 sets, milling machine 11 sets. We have a group of experienced high-level processing technicians. Our products are sent to the Metrology Institute for random inspection every year regularly and issue inspection report.

Have the industry leading level of the designer, can strictly grasp the product design and processing precision.

We have experienced and skilled assembly master.

Our products from the design concept, the processing technology, the assembly technology omni-directional control.Provide high quality products for users.

If our standard products do not meet your requirements, we can customize them according to your requirements.

We are glad that you can cooperate with us.,As the journey is far away, please be sure to see the parameters or communicate with our sales when selecting the product, Avoid buying wrong products to delay your use..