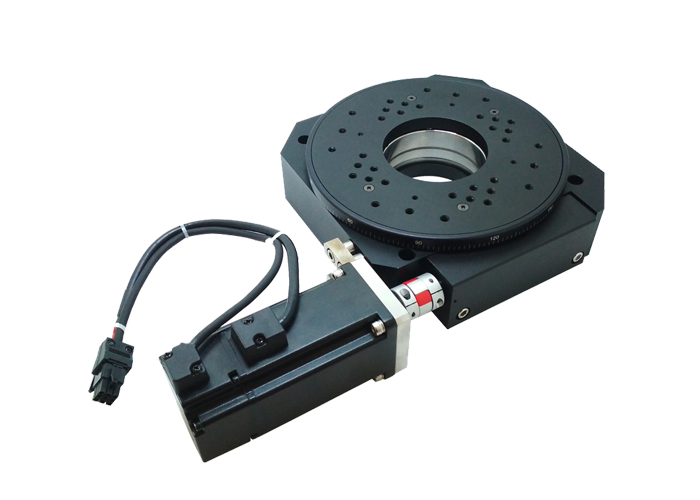

Product description

1. The standard stepping motor can be controlled automatically by the motion controller independently developed by our company.

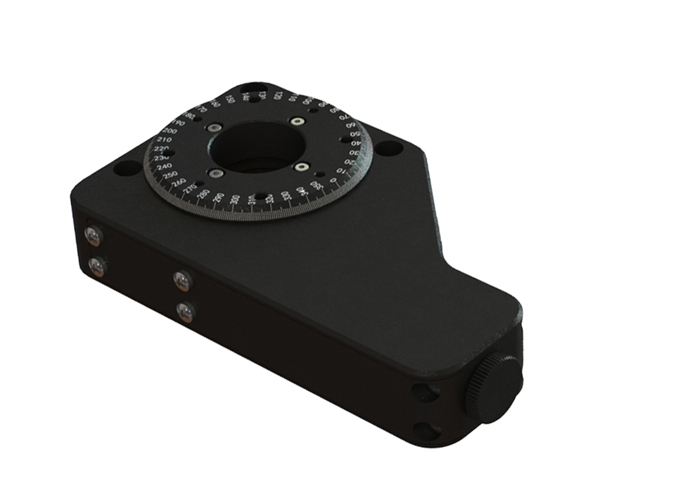

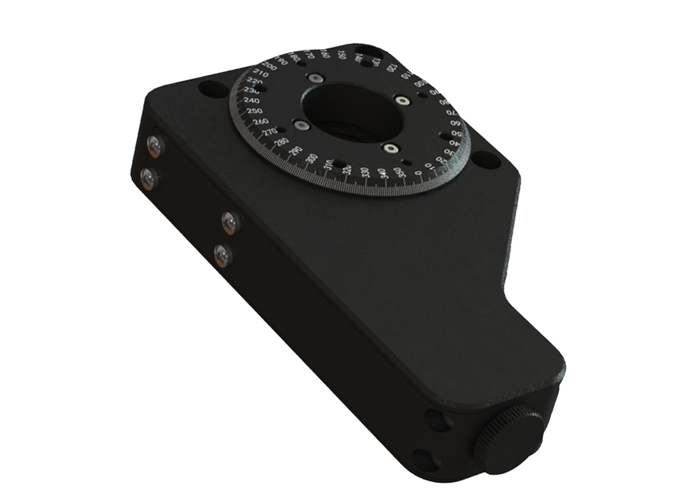

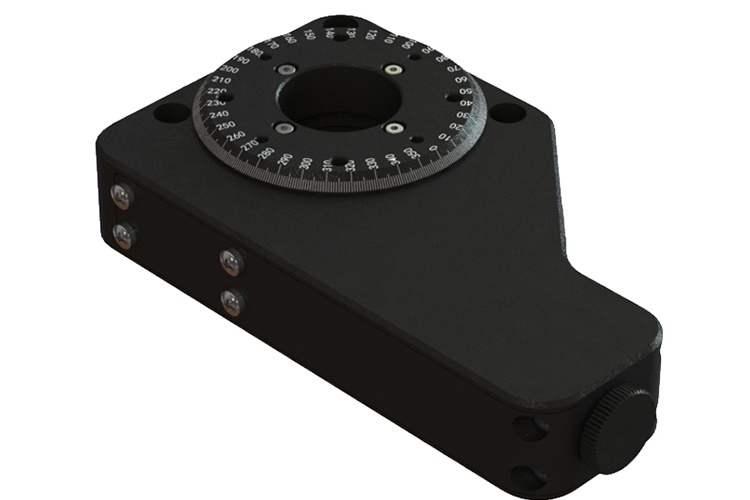

2. The rotating shaft system is precisely processed by multiple processes, ensuring the accuracy and stability of rotation. It has large bearing capacity and long service life in the same size.

3. It adopts the worm gear and worm structure with precise research and matching, which is comfortable in movement.

4. It has clearance adjustment mechanism, which can greatly reduce the return difference.

5. Exquisite structure design, ultra-thin product shape.

6. The table has precise optical scale.

7. Electronic zero

Product Specification

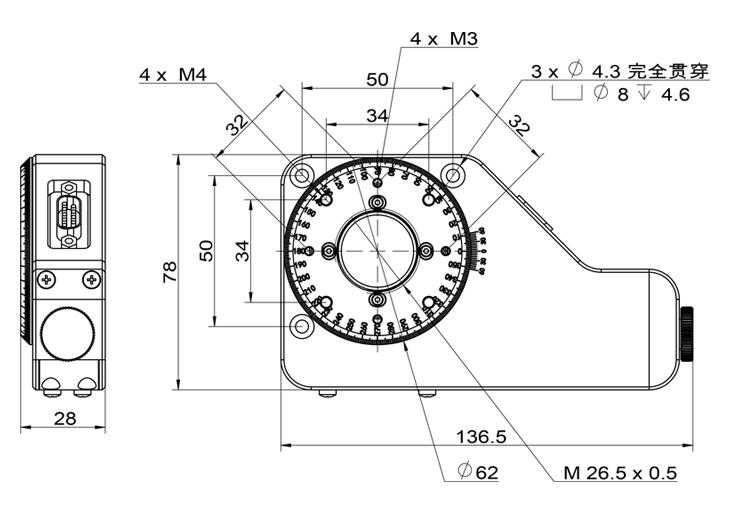

Model Number | PT-GD62 |

Platform Size | Ø62 |

Rotary Travel | 360° |

Transmission Ratio | 1:90 |

Main Material | High Strength Aviation Aluminum (7075) |

Surface Treatment Of Main Materials | Black Anodizing |

Instrument Weight | 0.8Kg |

Center Load (Horizontal Motion)(Speed: 1°/S) | ≤5Kg |

Vertical Load (Vertical Motion)(Speed: 2°/S) | <1kg |

8 Subdivision Resolution | 0.0025° |

Max Speed(Load ≤1kg) | 5( deg/sec) |

One Way Positioning Accuracy | 0.05°/180″ |

Repetitive Positioning Accuracy | ±0.03°/108″ |

Backlash | ±0.03°/108″ |

Radial Runout | 40μm |

Axial Runout | 40μm |

Parallelism | 50μm |

Surface Runout | 30μm |

Motor Type | Double Output Shaft 20 Stepping Motor |

Motor Step Angle | 1.8° |

Rated Working Current | 1A |

Supply Voltage | 24V±10% |

Joint | DB9 Needle Connector |

Zero Switch | Hall Sensor |

Product Detail