Structure Specifications

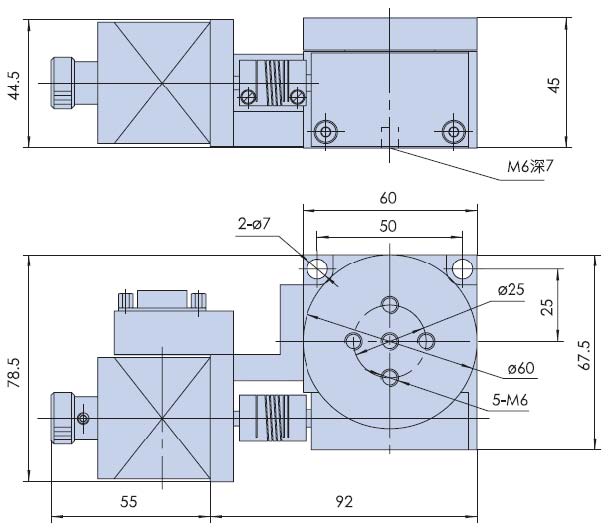

1 Item number:PX110-60

2 Rotation Range: 360° of Continuous Rotation

3 Diameter of Platform: Ø60mm

4 Drive Mechanism: Worm Gear

5 Worm Gear Ratio:45:1 or 90 : 1

6 Stepper Motor (1.8°): 42BYG - Stepping Motor with 2-Phases & 1.8° of Step Angle

7 Material – Finish: Aluminum Alloy - Black-Anodized

8 Load Capacity: 30Kgs

9 Weight: 1.2kgs

Accuracy Specifications

1 Design Resolution: 0.02°, Non-MS Driver; 0.001°=36”, 20MS Driver

2 Rotational Velocity (Max): 50°/sec

3 Repeatability: 0.05°=18”

4 Absolute On-Axis Accuracy: 0.01°=36”

5 Run-Out of Top Plate: 15μm

6 Backlash: 0.005°=18”

7 Eccentricity: 5μm

8 Lost Motion: 0.005°=18″

9 Parallelization: 80μm

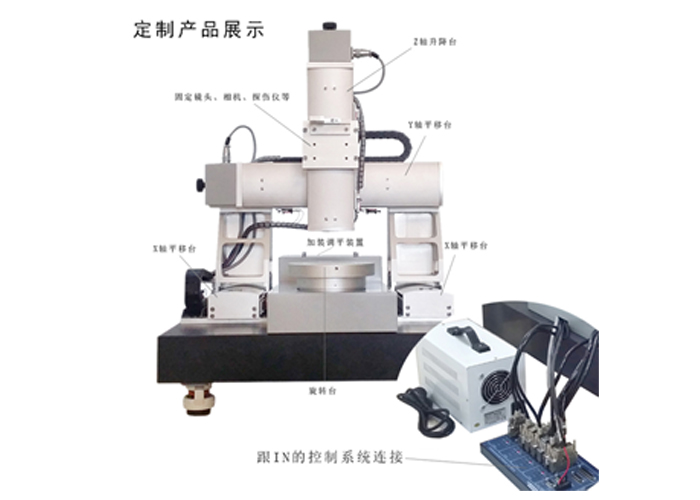

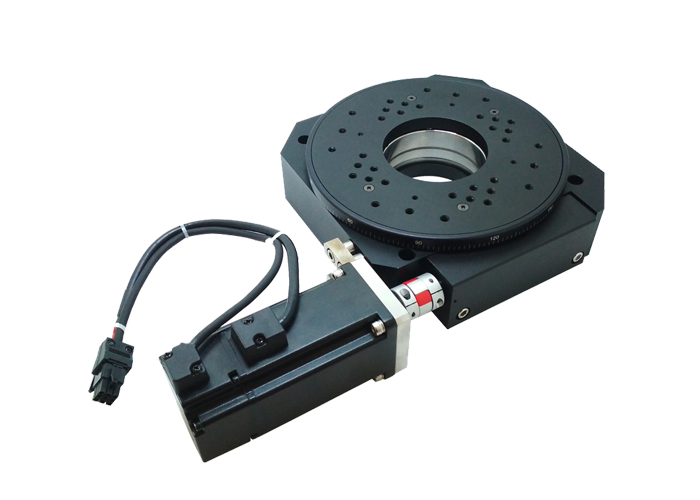

High Precision Motorized Rotation Stages

using New construction ,new technology;the key index has up to the international level of the similar products by strictly inspection .This series products are used to laser precision processing,three dimensional scanning measurment system and so on .

Worm and worm wheel has adopted durable to friction material ,high reliable accuracy of rotation .

High precision ,ultra steel axises of importing ,achieve high precision, high load stable motion.Outer circle has scale, interface , convenience for signal’s output.

1、

Standard stepper motor and DB9 interface, choose to controller flexibility ,We also can provide fully customized motion systems .

Regular stage set with stepper motor and RS232 interface, could connect with motion controller easily.

2、

*High precision Worm gear design for high accuracy, loading and long working time.

*Forward and reverse rotate are possible

*The stage could use in vertical and assemble with other stages

3、

1. Prototype stepper motor 42 stepper motor (1.8°). Servo motor available for replacement on request

2. Fine steel rotary shoe, high accuracy, massive loading capacity and long using life.

3. Fine grinding worm drive with comfortable movement and backlash can almost ignored.

4. Clearance elimination design.

5. The motor is connected with the worm via high quality elastic coupling, synchronized drive without noise.

6. Scaling on the outerring of the platform, easy scale reading.

Have the industry leading level of the designer, can strictly grasp the product design and processing precision.

We have experienced and skilled assembly master.

Our products from the design concept, the processing technology, the assembly technology omni-directional control.Provide high quality products for users.

If our standard products do not meet your requirements, we can customize them according to your requirements

We are glad that you can cooperate with us.,As the journey is far away, please be sure to see the parameters or communicate with our sales when selecting the product, Avoid buying wrong products to delay your use..