The product does not include the controller, and the controller is ordered separately

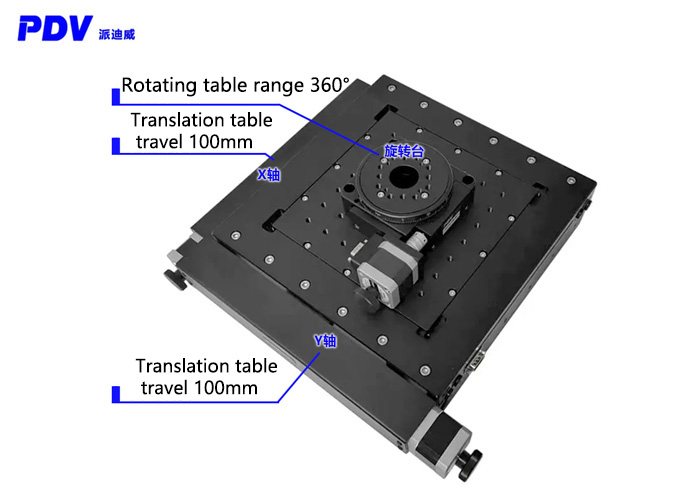

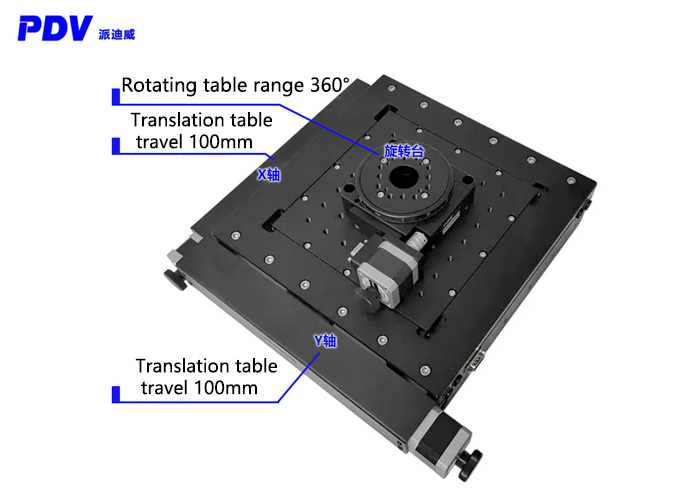

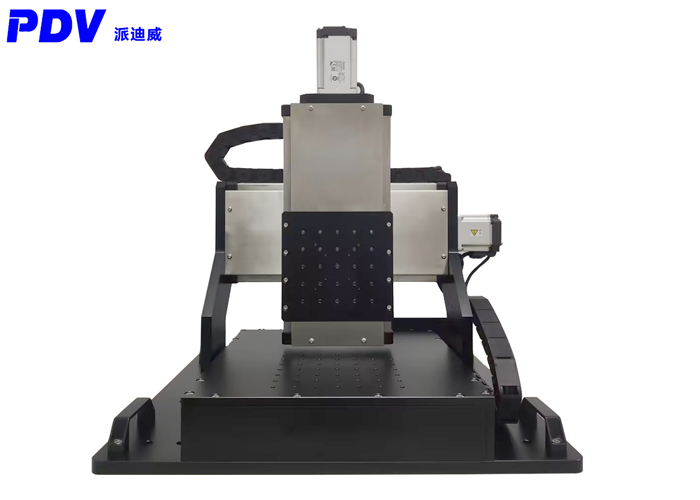

Electric Integral Combination Stage: PT-XY100

Product features:

※ stepper motor is equipped as standard, which can be automatically controlled by the company's motion controller.

※ the product is small and light in structure, which is suitable for use under light load and low speed, as well as in scientific experiments.

※ high quality fine grinding lead screw drive, small lead, the same fine fraction can achieve high resolution.

※ the ingenious structural design of air elimination check nut can minimize the clearance of grinding lead screw pair.

※ the precision square guide rail is comfortable to move, and has the function of laterally adjusting the guide rail preload and eliminating clearance. It can be used in multi-dimensional combination.

※ the fine grinding of the bottom plate of the electric moving table and the reasonable fixing mode of the guide rail greatly reduce the pitch and yaw of the electric moving table, and greatly improve the straightness and parallelism of the movement.

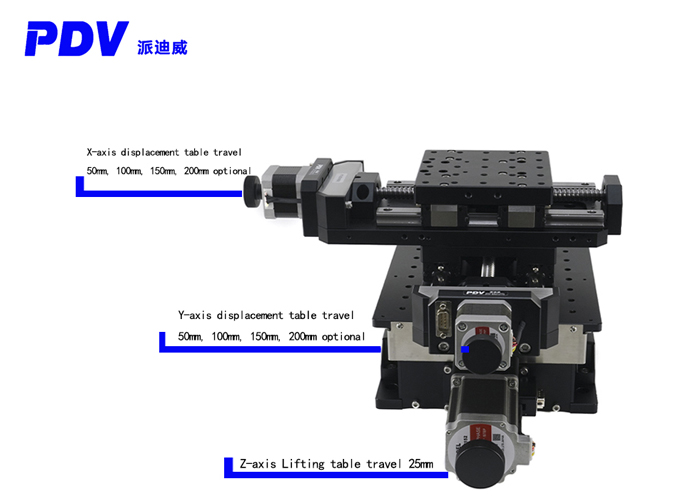

Product parameters:

Model Number | PT-XY100 | |

Structure | Travel Range(mm) | 100mm |

Platform(mm) | 300mm x 300mm | |

Screw Guide | 4 | |

Travel Guide | Precise Crossed Roller Bearing | |

Stepper Motor | 42(1.8°) | |

Material | Aluminum Alloy | |

Surface Preparation | Black-Anodized | |

Load Capacity(Kg) | 50 | |

Weight(Kg) | 8.3 | |

Accuracy | Resolution(μm) | 20(Non MS), 2.5(8 MS) |

Velocity | 40mm/sec | |

Repeatability(μm) | 2 | |

Absolute Accuracy(μm) | 3 | |

Straightness(μm) | 5 | |

Moving Parallelism(μm) | 15 | |

Pitching | 50" | |

Yawing | 25" | |

Backlash(μm) | 2 | |

Lost Motion(μm) | 2 | |

Accessory | Installing Grating Ruler (Optional) | |

Reloading Servo Motor (Optional) | ||

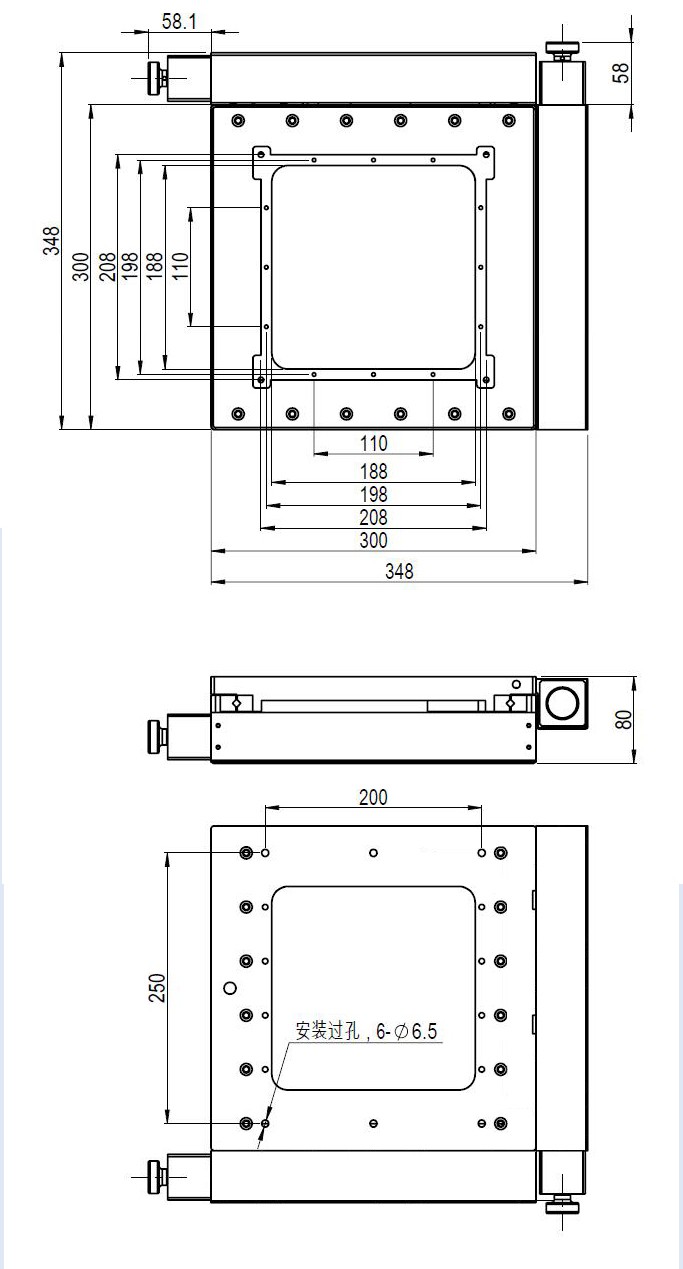

Product dimension drawing:

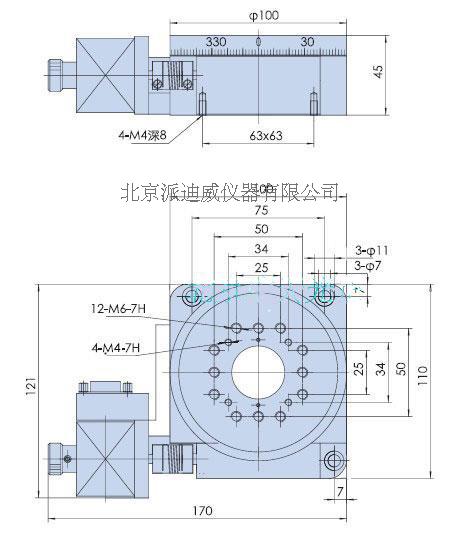

Precision Electric Rotary Stage (Worm Gear): PX110-100

Product parameters:

Model Number | PX110-100 | |

Structure | Rotation Range | 360° |

Platform Size | φ100mm | |

Transmission Ratio | 180∶1 90:1 | |

Drive Mechanism | Worm Gear | |

Travel Guide | Bearing | |

Stepper Motor (1.8°) | 42BYG | |

Material Surface | Aluminum Alloy (Black-Anodized) | |

Central Load | 45kg | |

Weight | 1.7kg | |

Accuracy | Design Resolution | 0.01°(Non-MS Driver) |

0.0005°=1.8″(20MS Drive) | ||

Velocity | 25°/sec | |

Repeatability | 0.005°=18″ | |

Absolute Accuracy | 0.01°=36″ | |

End jump accuracy | 15μ | |

Backlash(μm) | 0.005°=18″ | |

Eccentricity | 5μ | |

Lost Motion(μm) | 0.005°=18″ | |

Parallelism | 80μ | |

Product dimension drawing:

PX110-100

We have Processing equipment: CNC 10 sets, Lathe 8 sets, milling machine 11 sets. We have a group of experienced high-level processing technicians. Our products are sent to the Metrology Institute for random inspection every year regularly and issue inspection report.

Have the industry leading level of the designer, can strictly grasp the product design and processing precision.

We have experienced and skilled assembly master.

Our products from the design concept, the processing technology, the assembly technology omni-directional control.Provide high quality products for users.

If our standard products do not meet your requirements, we can customize them according to your requirements.

We are glad that you can cooperate with us.As the journey is far away, please be sure to see the parameters or communicate with our sales when selecting the product, Avoid buying wrong products to delay your use.