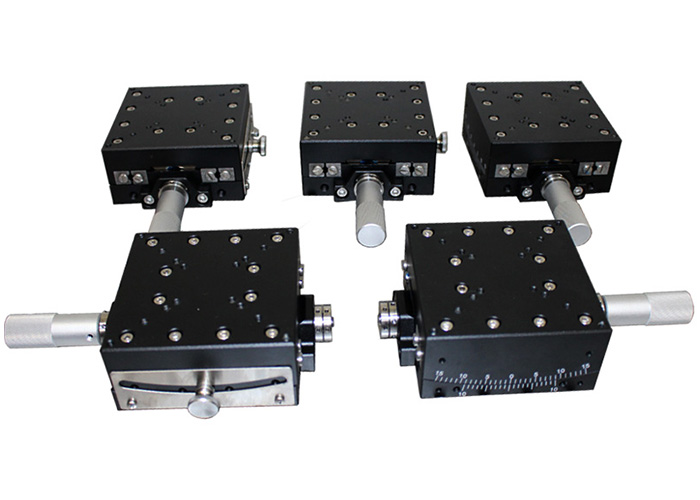

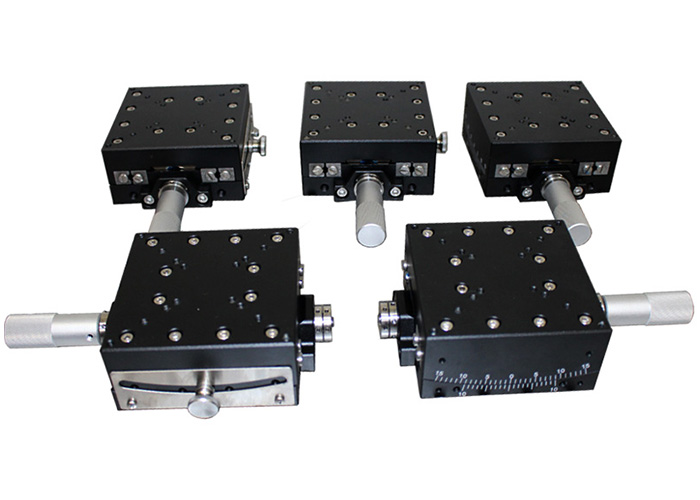

The main material of the manual angle position stage is made of high-strength aluminum alloy, guided by ultra-high precision arc cross roller guide rail, driven by a micrometer, the table runs smoothly without return clearance, and the swing accuracy of the rotation center reaches the international level. This product is suitable for the field of ultra-high precision manual adjustment, especially the precise adjustment of optical fiber coupling or optical waveguide devices, DPSS laser components, and can also be used in vacuum (vacuum grease replacement is required).

Features of manual angle position stage:

1. Worm gear and worm drive, large transmission ratio, with self-locking function;

2. Can be used independently or in pairs;

3. Product size is rich, delivery time is short, matching is good, cost-effective;

4. The arc V-shaped ball guide rail is used for comfortable movement, strong load capacity and good durability;

5. Precision machining of the guide rail mounting surface ensures the high sensitivity and high movement accuracy of the product;

6. The main material is 6061 aluminum alloy with black oxide treatment on the surface, which has high strength, good wear resistance and beautiful appearance.

At present, the products can be selected according to the customer's industry: plastic handwheel, folding handwheel and aluminum alloy handwheel; The slide table can be equipped with angle ruler, position display, revolution counter or gravity indicator through the handwheel; The manual angle position stage is driven by the hand wheel and the trapezoidal screw rod with single head, multiple heads or left and right split. The slide table and base frame can be equipped with indicator ruler and indicator plate to detect the workpiece accuracy.

Application site of manual angle position stage:

Tooling clamping, loading and positioning, automatic workstation, semiconductor equipment, TFT-LCD LCD panel equipment, solar equipment, LED online equipment, XYZ axis working platform inside the machine, dispensing, locking screws, visual inspection, measuring equipment, etc., high-speed and high-precision places.