The displacement table products are divided into different models, electric displacement table series products and Manual Displacement Station products according to different driving methods. The displacement platform is widely used in industrial, vacuum, aseptic, etc. What is the difference between the two? How to choose the stage product?

The electric displacement table series products have the advantages of high precision, rapidity, large load, large stroke and automation. They are widely used in scientific research, laser applications, automatic measuring instruments and equipment, industrial automation and other fields to achieve vacuum, pollution and sterility. Automatic displacement control in environments such as radiation.

The electric displacement system basically consists of three parts: the displacement stage, the drive motor and the control box. The drive motor and control box mainly determine the driving torque, resolution, acceleration and deceleration, signal processing, use function and other performance parameters. The stage is the heart of the system. The main technical indicators such as displacement accuracy, stroke, load, stability, applicable environment, and external dimensions are determined by it.

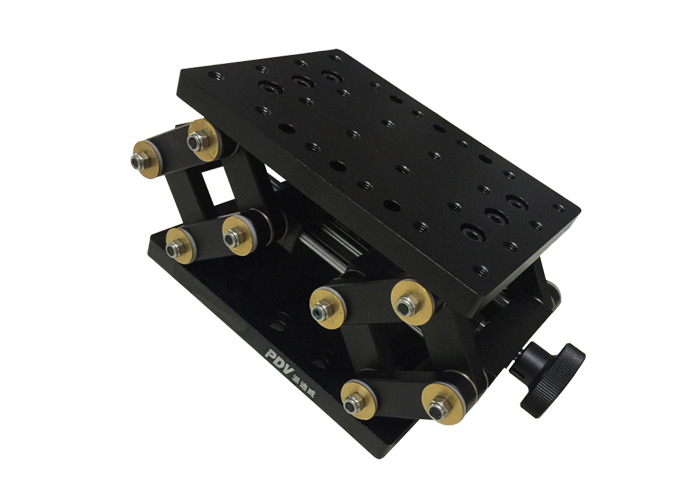

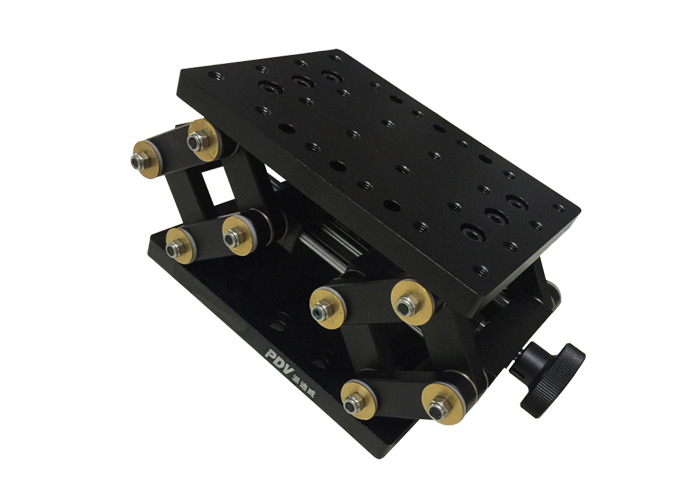

The manual displacement table series is mainly used for six spatial freedom adjustments such as translation, lifting and rotation of objects, and is suitable for applications with low automation and infrequent adjustment.

According to the China Electric Lifting Platform Supplier , there are many models of manual displacement table series and electric displacement table series, which are suitable for use in different environments and can achieve different effects. Therefore, when purchasing a stage product, I suggest you consult the manufacturer of the stage.