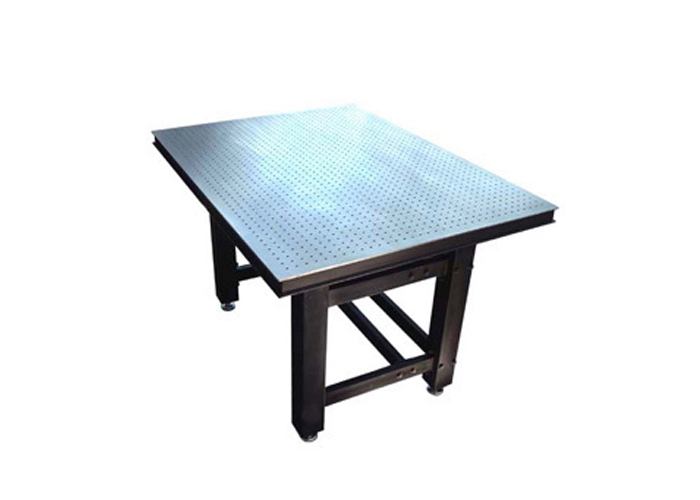

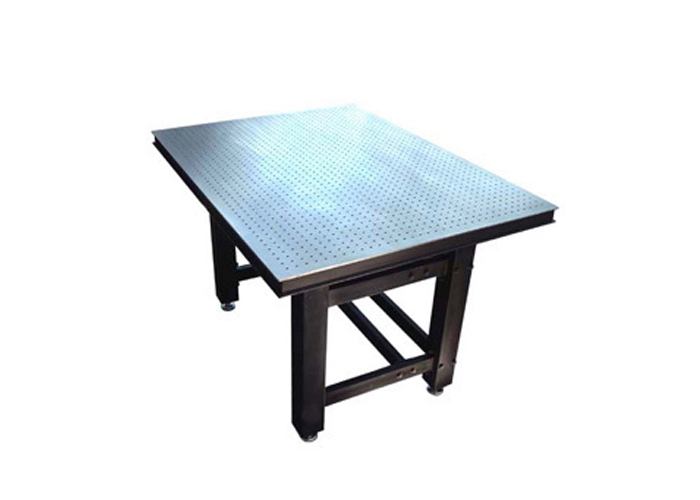

The optical stage system consists of an optical table and vibration-isolating legs. The optical table is used to hold the instrument and control vibration. When a vibration source is transmitted to the tabletop, the tabletop honeycomb structure and damping can effectively reduce the vibration deformation of the optical stage.

In addition, to support, the main function of the vibration isolating legs is to isolate vibrations from the ground, and vibration isolation performance is one of the most important indicators. Other features include independent leg height adjustment, automatic leveling, load capacity, selectable height, and the presence of magnetism.

PDV Instruments has been serving scientific institutes and universities since 2005. By developing hardware and software systems (optical path construction, software development, mechanical circuit design, etc.) to build systems to control optical paths according to customers' needs and providing quality service to the process, PDV has grown to be a well-known manufacturer in many fields such as scientific research, universities, and mechanical automation. Different thicknesses and sizes of optical stages are available to meet any performance and budget needs.

Sources of vibration

Most optical experiments or industrial production require a high degree of system stability. Vibrations caused by various factors can cause instability and inaccuracy of instrument measurements, which can seriously interfere with production and experiments.

The sources of vibration can be divided into vibrations from outside the system and vibrations from inside the system. The vibration from the ground, the staff step on the floor and open, close the door or wall collision through the ground are all vibration outside the system, and this kind of vibration needs to be attenuated by the vibration isolation leg of the optical platform; while the vibration from inside the system, including instrument vibration, airflow, cooling water flow, etc., need to rely on the table damping of the optical platform to isolate.

Vibration Fundamentals

Intrinsic Frequency

The intrinsic frequency is, as the name implies, the frequency at which the system itself vibrates. Numerically, the intrinsic frequency is equal to the resonant frequency. Considering a system consisting of a mass and an elastic cantilever, the intrinsic frequency depends on two factors - the mass of the mass and the coefficient of elasticity of the elastic cantilever acting as a spring. Decreasing mass or decreasing coefficient of elasticity increases the natural frequency; increasing mass or increasing coefficient of elasticity of the cantilever decreases the natural frequency.

Damping

Without damping, the system would vibrate for a long time - at least a few seconds - before coming to rest. Damping consumes the mechanical energy of the system, causing it to decay more rapidly. For example, when the tip of a tuning fork is immersed in water, the vibration decreases almost immediately. Likewise, when a finger touches a resonant mass - a cantilever beam system - the damping device rapidly consumes the vibration energy.

If you want to get more information about good quality optical stages, please contact us.