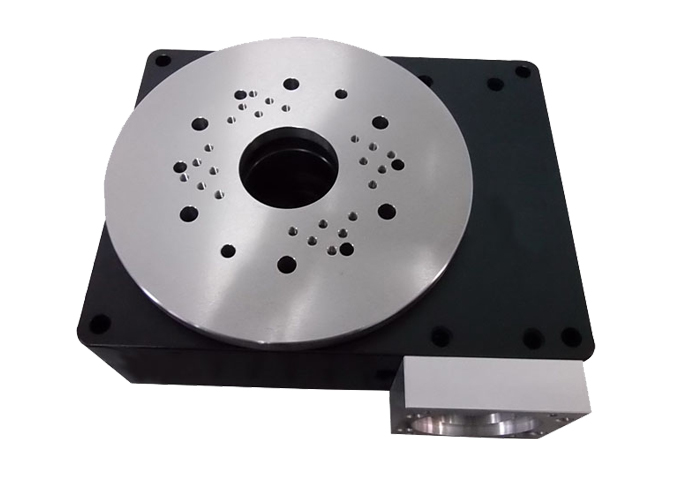

Motorized Rotation Stage full electronic control translation platform:

electronic control system consists of three parts: the basic translation

translation (mechanical part), the drive motor parts (driver), the controller

(control). The drive motor and controller mainly decided to drive torque,

resolution, add and subtract speed, signal processing, to use a function (such

as scanning, circular arc interpolation). Performance parameters, such as

translation is the heart of the system, the main technical indexes such as

translation accuracy, stroke, load, stability, suitable environment, the size

are decided by its shape.

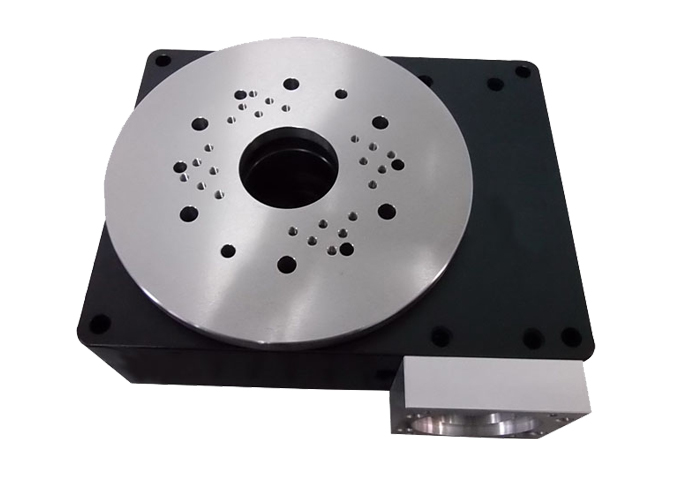

Manual Rotation Stage compared with electric translational platform mainly is

to drive some changes to the handwheel, and remove the control part, directly

use the hand to artificially control the accurate translation. Manual

translation because of its simple driver, use agile, also widely used in a

variety of precision translation needs to be done without the need for online

automatic control occasions.

What are the characteristics of the Motorized Rotation Stage?

Electric machine translation to be able to convert rotary motion of the motor

quantitative into linear motion, the energy conversion efficiency can reach 70%

(ball screw). The indicator directly increase the load capacity of electric

translation machine. Electric translational motion precision is high.

Positioning accuracy and repeat precision can reach micron grade. For example:

if the drive motor for stepper motor, step away from the Angle of the motor is

1.8 °. Drive screw pitch of 4 mm. Need 200 step motor rotation on the

translation reflects the linear translation for screw pitch . 4 mm. So every

step motor action. Electric displacement linear translation is 4/200 = 0.02 mm.

Another step motor drive with functions of pulse subdivision. Each movement of

the motor can be subdivided. If using 8 segmentation. So every motor. The

electric displacement platform can achieve sub-micron linear translation

theory.

Change different motion transformation form, can realize high speed movement.

In many applications, the need to improve the speed of movement of the

translation. In such cases, the electric displacement platform will often appear

such forms. Drive for high speed servo motor and drive for a big pitch screw, or

gear rack transmission. Cog belt, etc. So the premise of without sacrificing

accuracy and stability, improves the speed of the movement. Electric

translational combination machine, can make its are installed on the tool to

reach any point on the three dimensional space. Through linear interpolation

control, can realize complex trajectory.

This kind of slide table is widely used in machine tools. When the workpiece

is fixed on it, interpolation motion can be realized by controlling the motor.

It can make the workpiece's plane motion track become complicated and

changeable.

Want to know more about electric translation platform information, welcome to

inquire